The role of fibre testing equipment in quality assurance production environments

Wiki Article

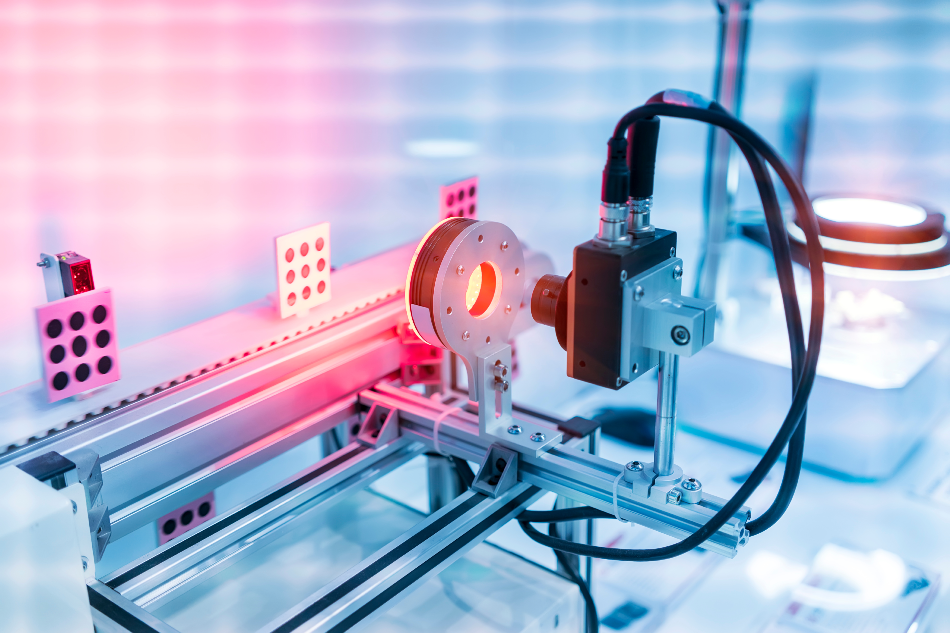

Why Robotic Vision Is Important for Progressing Accuracy in Production Industries

Robotic vision has actually arised as a critical element in modern production. It equips devices to examine aesthetic information with exceptional accuracy. This ability boosts top quality control and minimizes the possibility of flaws. As industries venture for higher performance, recognizing the intricacies of robotic vision ends up being important. The interplay between technology and functional procedures elevates vital concerns concerning future advancements and their ramifications. What exists in advance for accuracy in manufacturing?Understanding Robotic Vision Innovation

Enhancing Quality Control With Robotic Vision

Improving Functional Efficiency With Automation

Automating production processes through robotic vision significantly improves manufacturing rate, permitting quicker turnaround times. This modern technology additionally lessens mistake prices, guaranteeing higher precision in operations. Furthermore, structured source administration is accomplished, bring about more reliable use of materials and labor.

Enhanced Production Rate

While the combination of robotic vision in manufacturing has actually transformed functional processes, its most considerable advantage depends on boosted production speed. By utilizing innovative image processing and real-time data evaluation, robotic vision systems can promptly determine and react to production needs. This sped up responsiveness removes delays frequently related to hands-on examination and decision-making processes. Additionally, these systems can run constantly without fatigue, making certain that manufacturing lines preserve high throughput. The ability to find and address problems instantaneously additionally simplifies process, enabling producers to enhance result degrees (fibre testing equipment). Subsequently, business take advantage of reduced cycle times and boosted performance, positioning them competitively out there. Improved production speed, driven by robotic vision modern technology, eventually leads to enhanced functional efficiency throughout the production landscapeMinimized Mistake Rates

As manufacturing speed rises, preserving precision becomes critical in making procedures. Robotic vision systems substantially add to reduced error prices by providing exact dimensions and real-time analyses. These advanced systems make use of high-resolution electronic cameras and advanced formulas to detect defects, imbalances, or incongruities in items throughout setting up. By automating top quality control, suppliers can promptly recognize and rectify problems that human examiners may forget. This not only lessens waste but likewise enhances total item high quality. Furthermore, the assimilation of robotic vision minimizes variability in manufacturing, making certain that each product meets rigid requirements. Subsequently, producers experience fewer pricey recalls and raised customer contentment, inevitably leading to a much more reliable and lucrative functional design.Structured Resource Management

Efficient resource management is essential for maximizing operational effectiveness in production, specifically when integrated with robotic vision systems. These systems boost the ability to keep an eye on and allot resources accurately, making certain that materials and labor are made use of successfully. By using advanced visual technologies, manufacturers can identify inefficiencies in actual time, lowering waste and enhancing production timelines. On top of that, robotic vision enables precise supply tracking, minimizing the danger of overstocking or stockouts. Automation of these processes not only streamlines procedures however additionally allows human workers to concentrate on higher-value jobs, cultivating innovation and efficiency. Therefore, business can attain considerable price savings while preserving high-quality standards, eventually positioning themselves a lot more competitively in the industry.

Lowering Human Error in Production Processes

Human mistake remains a significant obstacle in making processes, typically resulting in costly blunders and inefficiencies. In atmospheres where precision is critical, even small gaps in judgment can result in defective products or hold-ups in manufacturing routines. Robotic vision systems can minimize these threats by offering precise and regular tracking of producing operations. By automating tasks such as top quality control and production line evaluations, these systems lower the dependence on human oversight, thus minimizing the possibility for errors.Moreover, robotic vision innovation boosts data accuracy, enabling real-time adjustments based upon aesthetic responses. This capability guarantees that any kind of variances from developed criteria are immediately recognized and dealt with, better reducing the possibility of errors. As suppliers progressively take on robotic vision, they can anticipate not only to improve precision and effectiveness yet additionally to cultivate a much safer working setting by relieving the stress on human drivers.The Function of Artificial Intelligence in Robotic Vision

Expert system substantially improves robotic vision by employing maker learning algorithms and advanced photo processing strategies. These technologies enable robotics to analyze visual data with greater accuracy, improving both efficiency and accuracy in producing setups. As an outcome, the assimilation of AI right into robotic vision systems stands for an essential improvement in automation.Artificial Intelligence Algorithms

Artificial intelligence algorithms are reinventing robotic vision in production by allowing machines to translate and evaluate visual information with remarkable accuracy. These algorithms allow robots to gain from huge datasets, adjusting to new situations and enhancing their performance gradually. By leveraging techniques such as supervised and unsupervised understanding, robotic systems can recognize patterns and anomalies in real-time, which boosts quality assurance and minimizes waste. Furthermore, maker knowing assists in far better decision-making processes, permitting robotics to optimize their activities based on found out experiences. As these algorithms evolve, they encourage robotic vision systems to execute significantly complicated jobs, ultimately driving effectiveness and accuracy in manufacturing operations. The combination of artificial intelligence as a result plays a crucial role in the improvement of robotic vision innovation.Photo Processing Techniques

Enhancing the abilities of robotic vision, picture processing techniques play a vital role in enabling systems to interpret aesthetic information successfully. These methods involve algorithms that enhance image quality, essence relevant features, and recognize patterns within visual data. By making use of methods such as side discovery, division, and item acknowledgment, robotic systems can determine and classify parts with exceptional accuracy. The assimilation of fabricated intelligence further intensifies these strategies, enabling adaptive discovering and boosted decision-making in vibrant environments. Therefore, robotic vision systems can not only find problems but likewise enhance procedures, bring about increased effectiveness and precision in production. Subsequently, the constant advancement of picture handling strategies stays essential to the development of robotic vision in commercial applications.Future Fads in Robotic Vision for Manufacturing Industries

As markets increasingly focus on performance and accuracy, the development of robotic vision technology is readied to change making processes considerably. Future trends show substantial developments in expert system and equipment knowing assimilation within robotic vision systems. These renovations will certainly boost real-time decision-making abilities, enabling robots to adjust to varying conditions autonomously. Additionally, the adoption of 3D vision systems is prepared for to boost, offering even more accurate spatial understanding and item recognition. Collaborations between robotics and human employees may additionally evolve, with advanced vision systems promoting safer and a lot more effective interactions. Furthermore, using side computing will likely allow faster information processing, reducing latency and boosting functional responsiveness. As these fads unfold, the production market stands to profit from boosted quality control, lowered waste, and streamlined operations, ultimately bring about increased competition in a swiftly changing market.Often Asked Questions

Exactly How Does Robotic Vision Differ From Traditional Device Vision Solutions?

Robotic vision includes sophisticated formulas and real-time handling, allowing vibrant interpretation and communication with environments. On the other hand, conventional equipment vision mostly concentrates on fixed photo capture and evaluation, restricting adaptability and responsiveness in optical measurement system complex manufacturing situations.What Industries Advantage The Majority Of From Robotic Vision Technology?

Various markets profit substantially from robotic vision technology, including auto, electronics, and food processing. These markets take advantage of enhanced accuracy, performance, and flexibility, inevitably boosting manufacturing top quality and reducing operational expenses via advanced automation services.Can Robotic Vision Solutions Be Integrated With Existing Production Devices?

Robotic vision systems can undoubtedly be incorporated with existing production tools. This integration enhances operational performance, permitting seamless cooperation between standard machinery and advanced visual innovation, inevitably boosting general production processes and outcomes.What Are the Costs Related To Implementing Robotic Vision Solutions?

The costs connected with carrying out robotic vision solutions differ considerably, influenced by elements such as system complexity, required software program, equipment components, combination with present equipment, and continuous upkeep expenditures, inevitably impacting total return on financial investment.How Do Maintenance and Assistance for Robotic Vision Systems Job?

Maintenance and assistance for robotic vision systems involve normal software program updates, equipment assessments, and troubleshooting. robotic vision. Suppliers commonly use service agreements, guaranteeing timely support and minimizing downtime to keep peak efficiency and reliability in industrial applicationsReport this wiki page